Let's Build Something Together

our culture

Where great products start with great teams

At United Alloy, we believe in supporting our employees both on and off the job. We’re committed to creating an environment where our team can thrive both professionally and personally. That means providing the tools, resources, and flexibility to help you grow, solve problems, and show up as your best self.

Together, we’re an agile team producing extraordinary results and setting the standard in:

- Safety

- Quality

- Productivity

- Profitability

Each employee brings a sense of ownership, takes initiative, and is deeply committed to the mission, the team, and themselves.

CAREER OPPORTUNITY SPOTLIGHT

Actively Hiring in Union, Ohio: Painters

Our newest facility in Union, Ohio is growing fast — and we’re shining the spotlight on the critical role of experienced painters.

All positions are eligible for medical, dental, vision, $3/hour premium for 2nd and 3rd shift, referral bonuses, 401K with match.

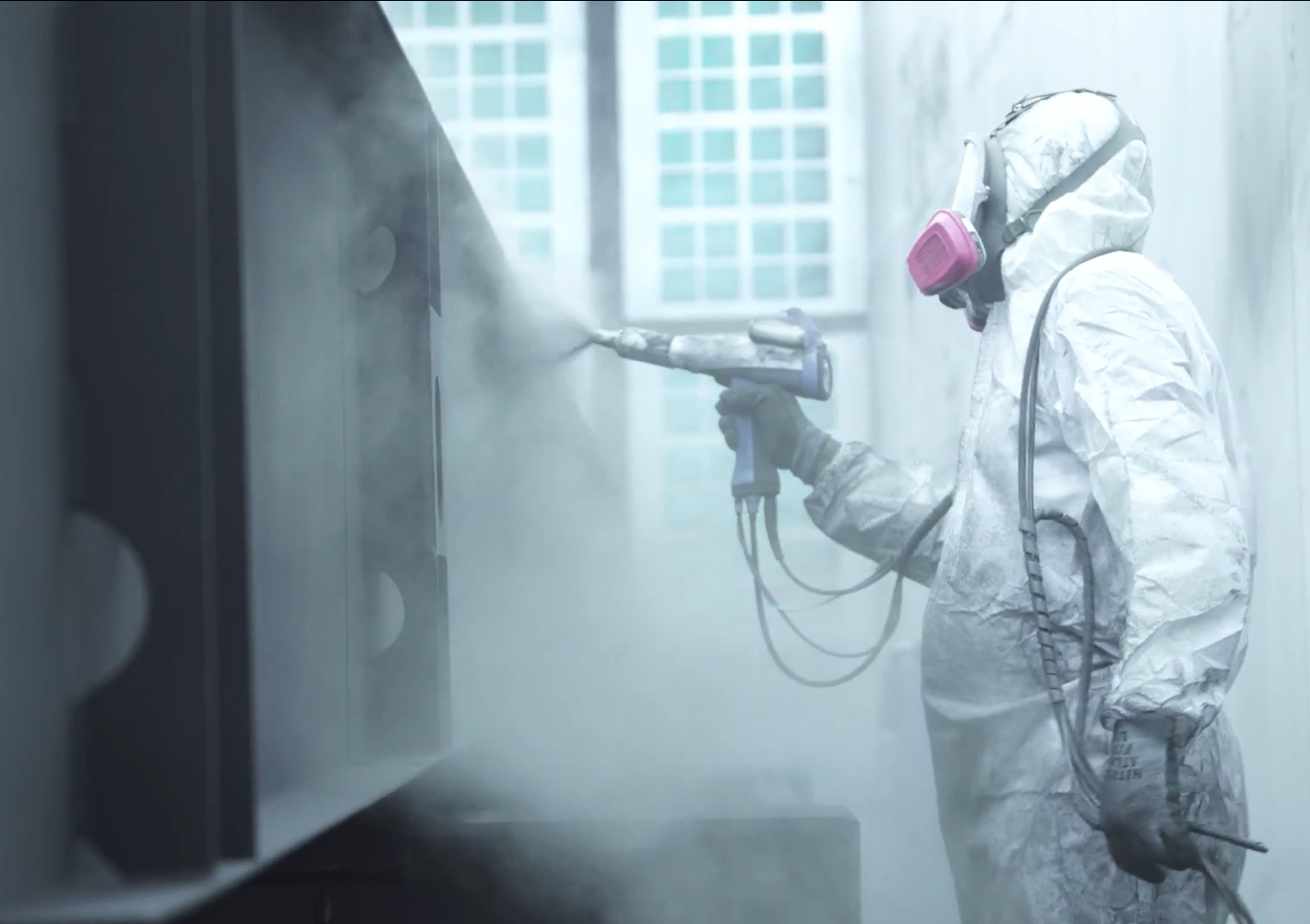

Powder Coat Painter

We're looking for skilled Powder Coat Painters! In this role, you'll apply high-quality powder coat finishes, adjust paint gun settings, troubleshoot equipment, and perform routine maintenance to keep the paint line running smoothly.

We're Hiring Experienced MIG Welders in Ohio

Why choose us?

- Match current pay, plus an extra $1.50 per hour*

- $3 shift premium for 2nd shift*

- Match current vacation time*

- Earn $2,000 for each welder you refer that we hire. No cap on the number of referrals.

- Medical, dental, vision, 401K, vacation/PTO, wellness programs, and LTD/STD/LIFE

* Valid through December 2025

- Match current pay, plus an extra $1.50 per hour*

Experience needed

- At least 1-3 years of experience and knowledge of MIG Welding

- Basic math skills and blueprint/schematic reading skills

- Pass a UAI/AWS D1.1 weld test

- At least 1-3 years of experience and knowledge of MIG Welding

Shift hours

- 1st Shift: 5AM - 3PM Mon-Thu

- 2nd Shift: 3PM - 1AM Mon-Thu

- Mandated overtime on Friday

- 1st Shift: 5AM - 3PM Mon-Thu

CAREER OPPORTUNITY SPOTLIGHT

We're Hiring Experienced

MIG Welders

Ready to make your mark in welding? Join our team to weld fabricated components based on custom and stock specifications, ensuring top-quality results for our customers. We’re looking for a skilled welder who can monitor performance and efficiency while adhering to United Alloy’s manufacturing standards.

If you’re passionate about precision and quality, this is the perfect opportunity for you! Apply today and be part of our success!

Opportunity starts here

Explore your future at United Alloy

Build with Us

If you like working with your hands, taking pride in precision, and being part of a team that builds real products, we’ve got a spot for you. Whether you’re an experienced fabricator or looking for your first shop floor job, we offer training, stability, and room to grow.

Business Behind the Build

Behind every weld and laser-cut part, there’s a team keeping things moving — from HR and finance to sales and operations. If you’re a problem-solver who thrives on collaboration and real-world impact, our corporate team might be the right fit for you.

Get Sparks Flying Early

Ready to learn a trade that lasts a lifetime? Our Youth Apprenticeship Program gives high school juniors and seniors (ages 16+) hands-on experience, one-on-one mentorship, and a direct path into the skilled trades. You'll explore five key areas in our state-of-the-art facility: fabrication, welding, assembly, paint, and shipping. This program is currently offered at our Wisconsin and Texas facilities.

Forging Futures

Our internship program gives college students the opportunity to turn ideas into impact through real-world projects. Interns collaborate, solve problems, and gain practical experience in their field of study and work alongside experienced professionals.

OUR COMMITMENT TO YOUR SAFETY

We put safety first, always.

We believe all injuries and incidents are preventable, and we're committed to our zero-injury culture. We provide the training and tools you need to work safely, and we expect every team member to look out for themselves and each other. Working safely isn't optional — it's part of the job. Safety isn't a policy. It's a promise we make to each other and to the people who count on us.

Hear from our team

Get the firsthand glimpse into the heartbeat of our organization

We believe that our people are the driving force behind our success. From seasoned Veterans who have grown with us, to the fresh faces shaping the future, discover why they chose a career with United Alloy. Explore the essence of our culture and learn what it truly means to be a part of the United Alloy family.

Courtney Michaels

Workforce Development Coordinator

Eric Meister

Manufacturing Process Engineer

Explore our most in-demand roles

MIG Welder

Joins metal components together using a welding machine that feeds wire and shielding gas through a gun.

Powder Coat Painter

Applies a durable, high-quality finish to metal parts using powder coating equipment.

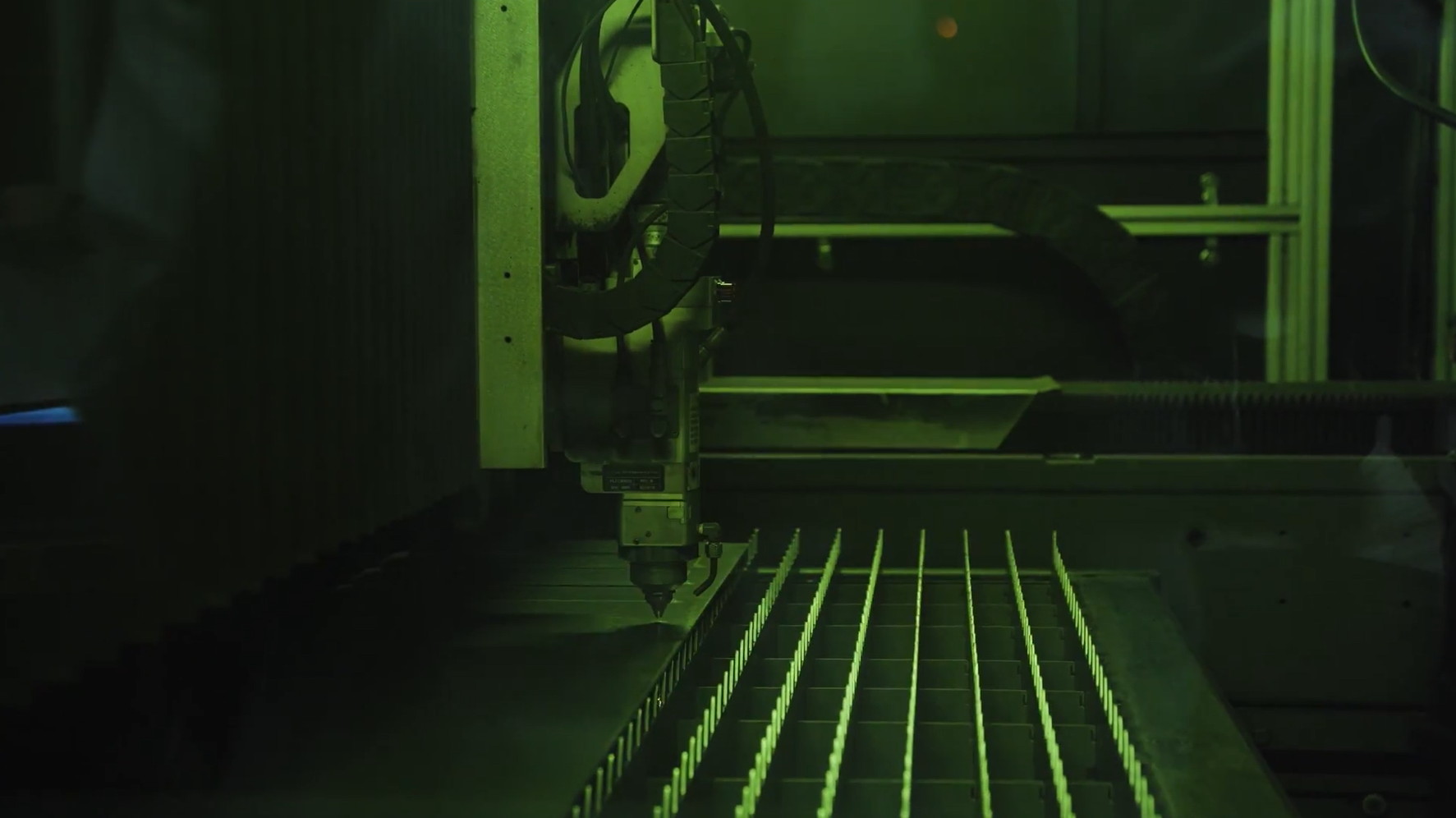

Laser Operator

Runs laser cutting machines that use high-powered lasers to cut sheet metal into precise shapes and parts based on engineering designs.

Saw Operator

Cuts raw metal materials to specified lengths or shapes using various industrial saws.

Press Brake Operator

Bends and forms metal parts using a press brake machine — a powerful machine that shapes sheet metal by clamping it between a punch and die.

Material Handler

Ensures that raw materials, parts, and finished products are moved, stored, and organized efficiently throughout the facility.

MIG Welder

Joins metal components together using a welding machine that feeds wire and shielding gas through a gun.

Powder Coat Painter

Applies a durable, high-quality finish to metal parts using powder coating equipment.

Explore our most in-demand roles and more!

Material Handler

A material handler plays a key support role, ensuring that raw materials, parts, and finished products are moved, stored, and organized efficiently throughout the facility. They help keep production flowing smoothly by supplying materials to machines and transporting items between departments.

Laser Operator

A laser operator specializes in running laser cutting machines that use high-powered lasers to cut sheet metal into precise shapes and parts based on engineering designs. This is a critical role in the fabrication process because it involves converting raw metal sheets into components used in assemblies or final products.

Saw Operator

A saw operator is responsible for cutting raw metal materials (such as steel bars, tubes, angles, or sheets) to specified lengths or shapes using various industrial saws. Their work is foundational — they prepare the stock materials that are later processed by welders, machinists, or press brake and laser operators.

Press Brake Operator

A press brake operator is responsible for bending and forming metal parts using a press brake machine — a powerful machine that shapes sheet metal by clamping it between a punch and die. This is a critical role for creating precision bends in components that go into everything from brackets and enclosures to structural

frames.

MIG Welder

A Metal Inert Gass (MIG) welder is responsible for joining metal components through using a welding machine that feeds wire and shielding gas through a gun. MIG welding is widely used in fabrication due to its speed, ease of use, and ability.

Powder Coat Painter

A powder coat painter applies a durable, high-quality finish to metal parts using powder coating equipment. This finish not only improves the appearance but also protects the metal from corrosion, wear, and the elements.